Node addresses can be selected manually or by the order in which devices are added to the system. Devices can be dragged into the program workspace from the toolbox and connections can be made by clicking on the ports of each device and dragging the connection line to the next device. In the physical view, the designer must lay out the network as it will be laid out in the field so that the system can address components accurately. The PowerLink network makes use of node addressing and can automatically address components on the network. B&R uses PowerLink network topology for its Ethernet protocol. Automation Studio uses this view to determine addressing within the network, if applicable, and provides a graphical representation of your project. This is where you lay out all the physical components within your system. Automation Studio’s physical view provides a graphical representation of your project with all of the physical components laid out in one place. This is beneficial for OEMs where they might have multiple versions of the same machine but with different hardware.įigure 2.

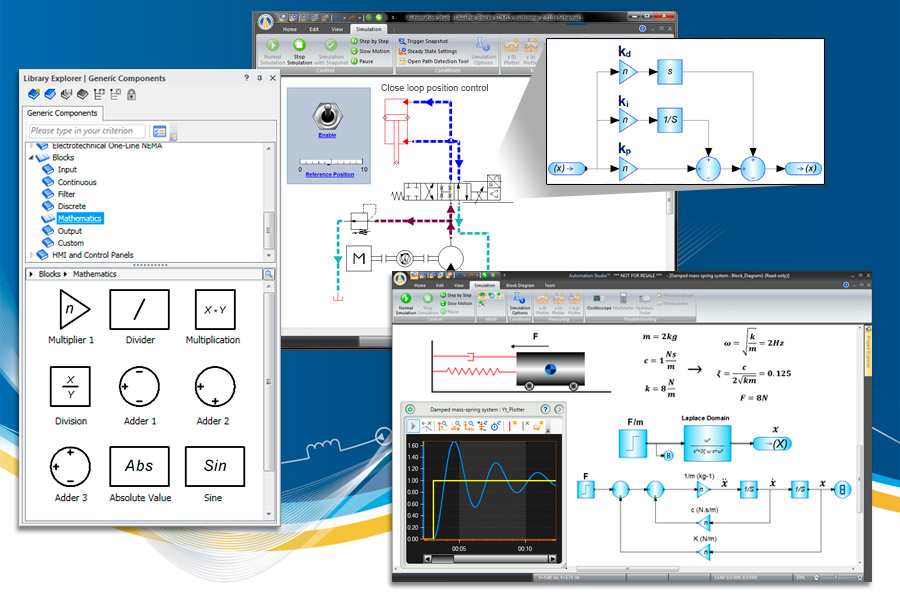

Each project can have multiple configurations and physical layouts, but they will all share the same logical view. The software is broken into three sections: the physical view, the configuration view, and the logical view. Image used courtesy of B&RĪutomation Studio is a fully integrated programming software, which means that the automation code, HMI, simulation, diagnostics, and hardware configuration are all contained inside of one software. Automation Studio’s automation code is all contained inside of one software. Below I’ll give an overview of how to use Automation Studio along with some tips that might make your next B&R project go a little bit smoother.įigure 1. Some automation programming software uses the IEC 61131 standard which offers five standard programming languages: ladder diagram, instruction list, function block diagram, structured text, and sequential function chart. Some software is completely integrated with motion control and HMI development, while other software focuses on just the automation component of the project. This software allows technicians and controls engineers to develop custom programs that interface with field components and troubleshoot those programs.

Every PLC or automation controller has its own programming software.

0 kommentar(er)

0 kommentar(er)